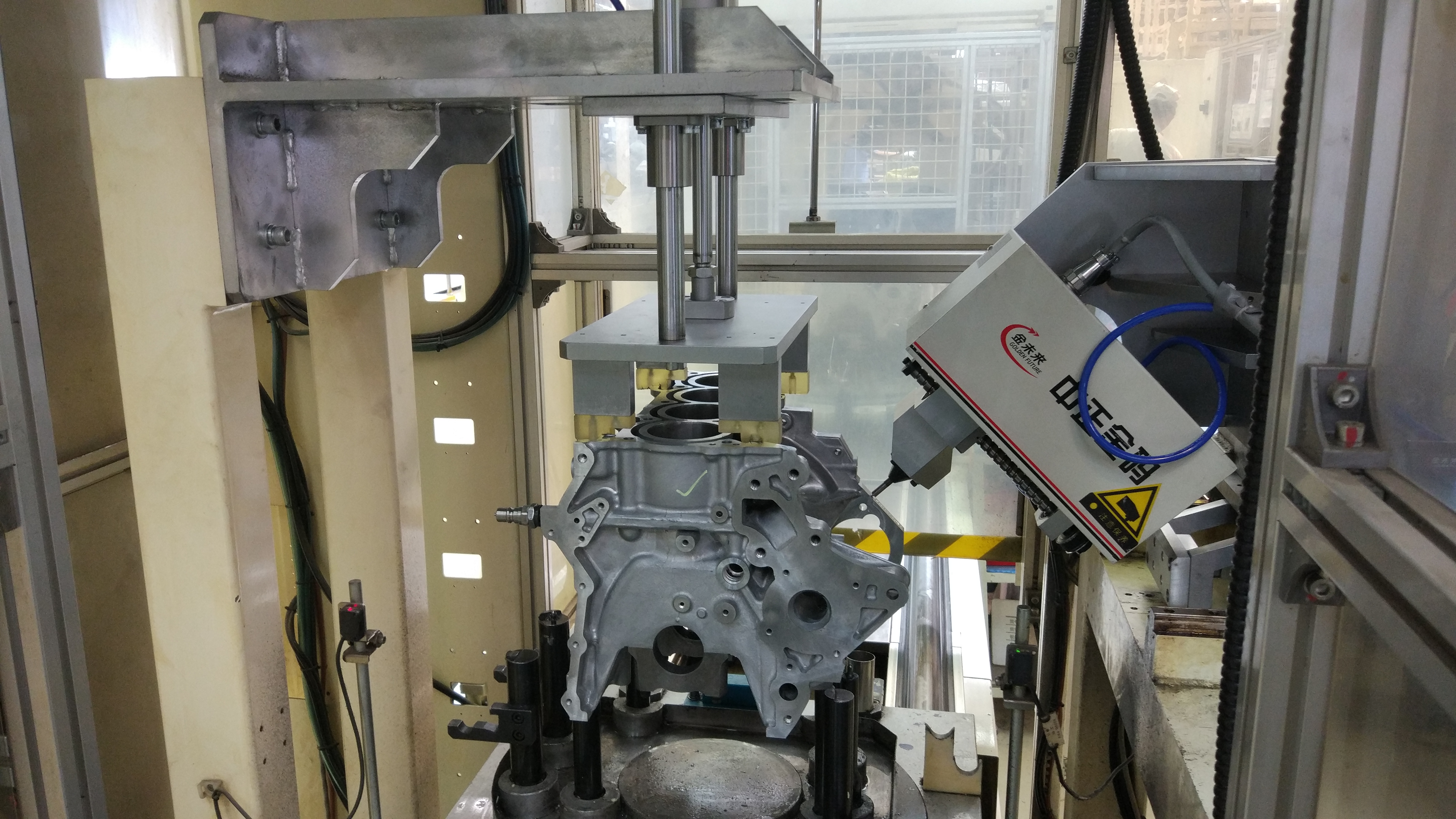

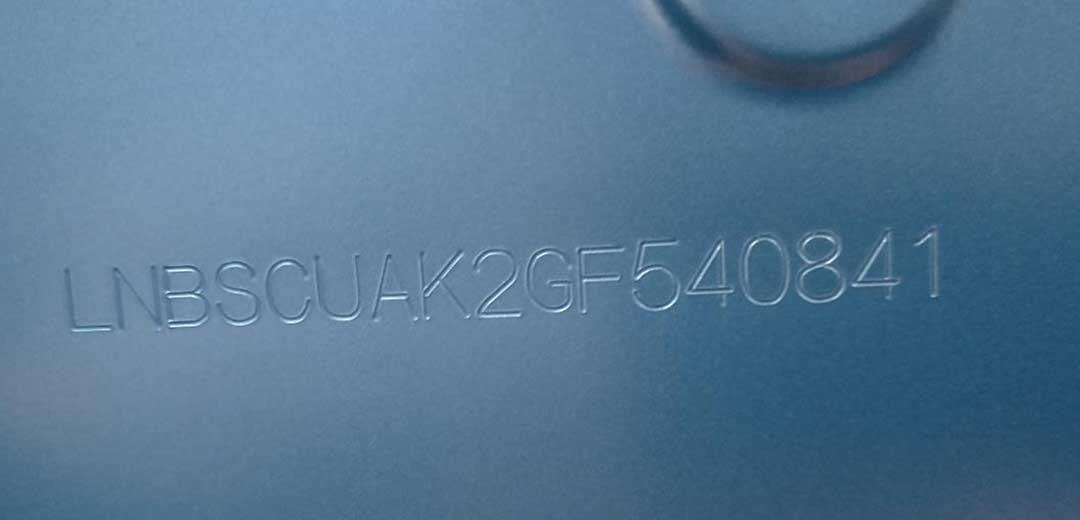

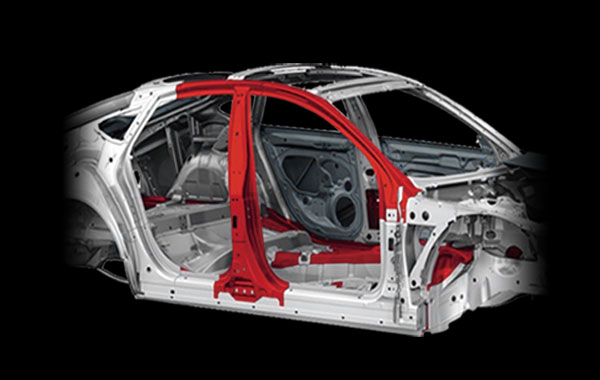

This product is primarily designed for VIN code marking on automotive assembly lines, meeting the requirements of the GB7258 national standard with a takt time less than 30 seconds. It is also suitable for engraving and marking of automotive parts. With its capability for fixed installation directly on the production line, it supports high-volume manufacturing demands. The marking depth and range are sufficient to address the needs for sheet metal VIN codes, body numbers, and printing on aluminum alloy cylinder body components.

Quiet: the device operates with a noise level ≤ 60 dB, making it suitable for environments with low noise requirements

Stable: the device features imported dual rails and precision ball screw transmission, ensuring smooth and precise operation

High-strength: the device is made of duraluminum-alloy, which not only enhances its aesthetic appeal but also provides high strength and lightweight characteristics

Marking Window: 155mm*55mm;

Depth: 0-0.4mm (varies according to the material);

Speed: 60 char/min (8*5 character);

Weight: 17.5kg;

Working Temperature: -10~40℃

Noise: <70 dB

Controller: Super-Engraving Servo Control Box (GFHSF2B01) / Integrated Controller (GF920AU-SF).

GF920 controller conducts marking based on WIN7/WIN10 system. It is small in size, light in weight, reliable in operation, and durable in stability. Motor operation is controlled by the application-specific integrated circuit, with the ability to run stably at high speed. It offers flexible and versatile installation options, including cabinet installation, wall mounting, and desktop placement. The device can be easily integrated into industrial control systems and supports secondary development.

What can we help you with?

-

Obtain quotation proposals and demonstrations

- Contact Us

-

Provide more product information

- Product Search

400-999-2511

400-999-2511 mail@kinmark.com

mail@kinmark.com