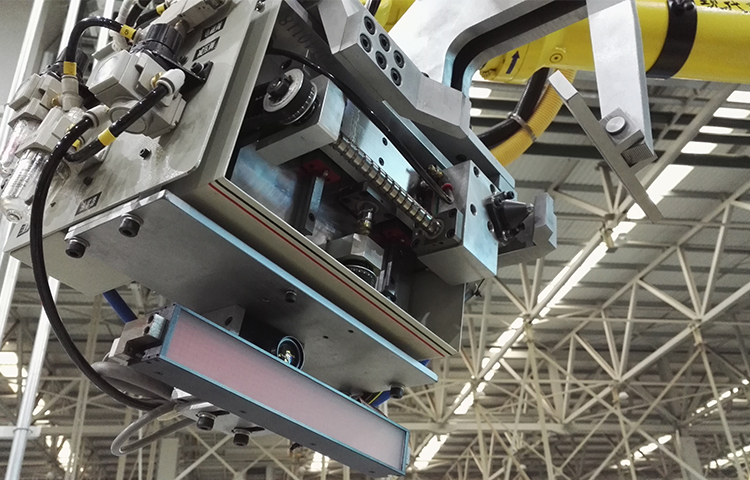

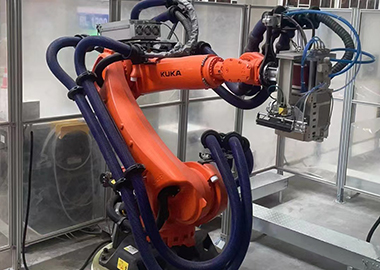

The visual recognition system consists of four parts, which are industrial camera, lens, light source, and computer (including software).

The functional changes brought by vision to engraving technology:

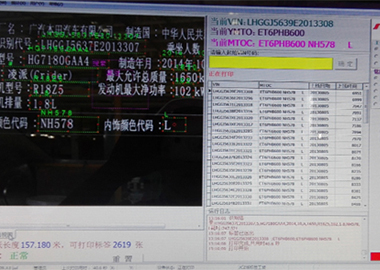

1. The closed-loop detection of data. After receiving the data, the engraving machine performs engraving, and the feedback channel is established between the engraving result and the received data by vision.

2. Remote monitoring of engraving effects. Remote monitoring of engraving effects can be achieved through visual technology and unlimited distance remote monitoring can be realized through network.

3. Graphical engraving history records. The engraved record can only be represented as a piece of data before adding visual effects and the specific effect of engraving cannot be verified. After adding visual effects, the engraving results can be saved in the form of images, making it easier to trace quality issues.

Recognition content: Variables in laser nameplates Technical Parameters: Ø Recognition tools: Positioning tools, Text recognition tools Ø Positioning accuracy: 1 pixel Ø Rotation angle estimation accuracy: 0.01 degrees Ø Positioning speed: 300ms~2s (fluctuating according to search area) Ø One recognition accuracy: over 99% Ø Recognition speed: 1 ms/character Ø Working resolution: 1280X1024. Higher resolution cameras are optional for special applications Ø Light source: Select according to the specific application to achieve the best lighting effect. Ø Computer: Conventional industrial computer Ø Software running environment: Windows XP or later operating systems. Ø Provide external communication protocol, and control the system through serial port or network according to the communication protocol. Ø Provide a redevelopment library, for easy integration with other software.

What can we help you with?

-

Obtain quotation proposals and demonstrations

- Contact Us

-

Provide more product information

- Product Search

400-999-2511

400-999-2511 mail@kinmark.com

mail@kinmark.com